Establishment of circular economy system for metal resources

Recycled lead is made by extracting metallic lead from waste lead acid batteries through collection and recycling processes. This recycled lead is used by lead-acid battery manufacturers as raw materials for manufacturing automotive batteries.

DS DANSUK is building a global supply chain for waste lead-acid batteries and contributing to the creation of economic values such as environmental protection and cost reduction while practicing resource circulation through recycling.

Additionally, we are securing competitiveness within the battery recycling industry by enhancing product reliability through registration of our recycled lead brand on London Metal Exchange (LME).

The purity of recycled lead is over 99.97% and has the same characteristics as primary lead.

Main raw material for internal combustion engine automobile batteries and various industrial batteries

Wire sheath, radiation shield, solder

Lead oxides (litharge, red lead)

| Product Name | Appearance | Product Specifications | Packaging Unit |

|---|---|---|---|

| Recycled Lead | INGOT | Pb 99.97% min | Ingot-Bundle (42Ingots) Net Weight 1,050kg Bending : PET Band |

Adding high value to recycled lead

Lead alloy is a product that is extracted and concentrated from waste lead acid batteries and precisely mixed with antimony and tin to improve hardness to compensate for the softness of lead.

DS DANSUK's lead alloy is supplied to various industrial fields, including automotive batteries, ribbons for solar panels, and solder alloys.

Precise control of lead, antimony, and tin content: Ensuring the reliability of customer-tailored lead alloys

Lead acid battery pole plates and connectors

Storage Battery / Terminal Connector / Type Metal / Casting Metal / Fishnet Sinkers/ Solder

| Product Name | Appearance | Product Specifications | Packaging Unit |

|---|---|---|---|

| Antimony Lead Alloy | JUMBO | To be decided after consultation with customer | Jumbo-Net Weight 1,000kg |

| Calcium Lead Alloy |

Providing comprehensive solutions for non-ferrous metals

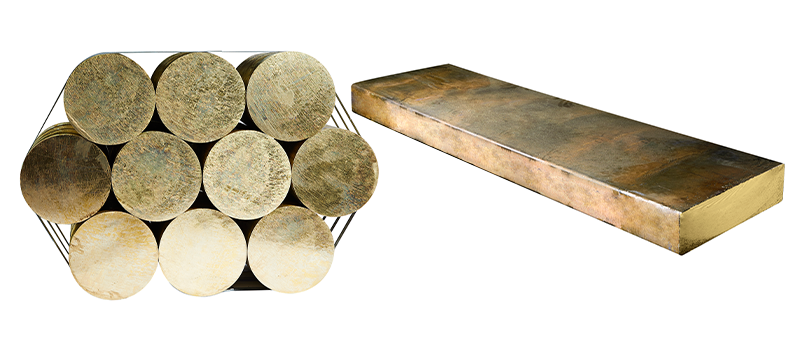

Copper and copper alloys are functional (high strength, high conductivity) copper products manufactured using electrolytic copper and copper scrap. DS DANSUK produces high-quality products with controlled composition and properties through the continuous casting process and supplies copper alloys with improved physical and mechanical properties and processability by utilizing electric induction furnaces to both domestic and international markets.

Cu 99.90% ↑

98% IACS ↑

Transformer / Switchboards / Electric Trams / Electric Vehicles

Zn 32~36%

Excellent processability and corrosion resistance

Switches / Connectors / Relays / Electric and Electrical / Automotive

Ni 10%

Excellent processability and corrosion resistance

Shipbuilding and Offshore Plants / Seawater-Resistant Valves / Pipes / Heat Exchangers

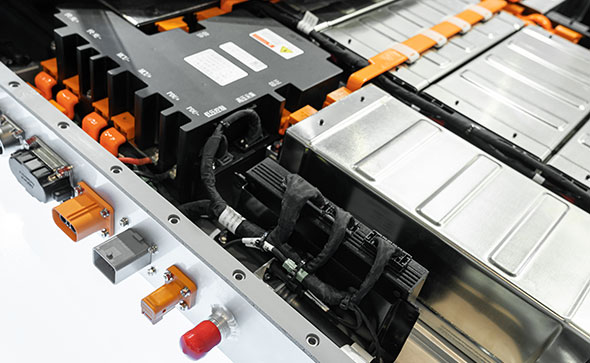

Basic Materials for LIB Recycling

Black mass is extracted from physically crushed waste lithium ion batteries (LIBs) and contains valuable metals such as lithium, cobalt, nickel, and manganese. DS DANSUK has a process to extract black mass, copper, and aluminum by recycling waste resources such as waste batteries and scraps generated during the process by discharging, crushing, grinding, and screening, and can produce about 5,000 tons of black mass per year.

Black mass contains metals at levels of 20-45% Ni, 5-15% Co, and 3-7% Li.

Forming a closed loop through the recovery of valuable metals in waste batteries

Used by LIB material (precursor, etc.) companies after refining into lithium carbonate, lithium hydroxide, nickel sulfate, and cobalt sulfate